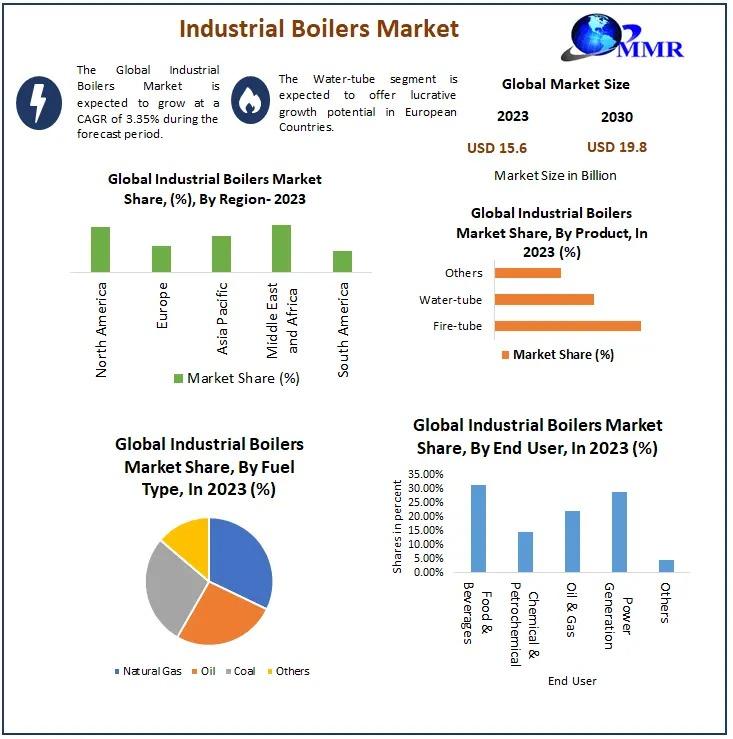

The Industrial Boilers Market Share is set for significant expansion over the coming years, with industry experts forecasting a market valuation of approximately USD 14.8 billion by 2030. This growth, driven by rapid industrialization, the need for energy efficiency, and continuous technological innovation, is expected to propel the market at a robust compound annual growth rate (CAGR) of around 7.5% during the forecast period.

Market Estimation and Definition

Industrial boilers are a cornerstone of modern industrial operations. Designed to produce steam or hot water, these boilers play a critical role in a variety of industrial processes, ranging from power generation and chemical processing to food production and pharmaceuticals. By converting various fuel types into usable thermal energy, industrial boilers facilitate a wide array of applications that are fundamental to maintaining efficient operations in heavy industries.

Get your Sample PDF: https://www.maximizemarketresearch.com/request-sample/24453/

Growth Drivers and Opportunities

Several key factors are fueling the expansion of the industrial boilers market:

-

Industrial Modernization and Expansion:

With rapid industrialization worldwide, particularly in emerging economies, industries are investing heavily in modernizing their processes. Many facilities are upgrading or replacing outdated boiler systems with state-of-the-art, high-efficiency models to reduce operational costs and improve overall performance. This modernization trend is especially pronounced in regions experiencing rapid industrial growth. -

Rising Demand for Energy Efficiency:

As energy demands rise and environmental concerns intensify, there is a growing emphasis on energy efficiency. Modern industrial boilers are designed to deliver higher efficiency rates while reducing fuel consumption and harmful emissions. Governments and regulatory bodies are also enforcing stringent emissions standards, which in turn push manufacturers to innovate and adopt cleaner technologies. -

Technological Advancements and Automation:

Advances in control systems, sensor technologies, and digital monitoring have revolutionized boiler operations. Newer models offer enhanced safety features, real-time diagnostics, and automated control, allowing for improved efficiency and lower maintenance costs. These technological innovations not only extend the operational life of boiler systems but also ensure compliance with evolving environmental standards. -

Expansion of End-Use Industries:

The industrial boilers market benefits from the expansion of several key sectors. The power generation industry, in particular, remains a significant end-user, as many power plants continue to rely on steam-based processes. In addition, sectors such as chemical processing, textiles, food and beverages, pharmaceuticals, and pulp & paper are increasingly integrating advanced boiler systems to enhance their production capabilities.

Access a Free Sample Report: https://www.maximizemarketresearch.com/request-sample/24453/

Segmentation Analysis

The industrial boilers market is broadly segmented by boiler type, fuel type, capacity, and end-use industry. Each segment reflects unique characteristics and market dynamics:

-

By Boiler Type:

- Water-Tube Boilers:

These boilers are known for their high-pressure capabilities and efficiency. They are widely used in power generation and large-scale industrial applications where high output and safety are paramount. - Fire-Tube Boilers:

Typically used in smaller or medium-scale operations, fire-tube boilers are valued for their simplicity and cost-effectiveness. They are commonly found in food processing, textile, and small manufacturing plants. - Electric Boilers:

Although less common in heavy industrial settings, electric boilers are gaining attention in niche applications, especially where space constraints and environmental considerations limit the use of conventional fuels. - Other Specialized Boilers:

This segment includes boilers that use advanced designs or alternative technologies to meet specific industrial needs, such as condensing boilers and combined heat and power (CHP) systems.

- Water-Tube Boilers:

-

By Fuel Type:

- Natural Gas:

Natural gas-fired boilers are favored for their cleaner combustion properties and high efficiency. The ready availability and competitive pricing of natural gas in many regions make it a popular choice. - Oil-Based Fuels:

Oil-fired boilers are used in industries where natural gas is not readily available. While traditionally common, their use is declining in regions with strict emission regulations. - Coal:

Despite its declining usage due to environmental concerns, coal-fired boilers remain significant in certain regions where coal is abundant and cost-effective. - Biomass and Waste-Derived Fuels:

The use of biomass and waste-derived fuels is rising, driven by sustainability initiatives. These boilers help industries reduce their carbon footprint while making efficient use of alternative energy sources. - Electricity:

Electric boilers are emerging as a viable option in applications where traditional fuels are not practical or environmentally sustainable.

- Natural Gas:

-

By Capacity:

- Small Capacity Boilers (Below 10 Ton/Hour):

Often used in small-scale manufacturing, food processing, and other similar applications, these boilers offer cost-effective solutions with lower energy outputs. - Medium Capacity Boilers (10-50 Ton/Hour):

Suitable for medium-scale industrial operations, these boilers balance efficiency and cost, catering to a wide range of industrial processes. - Large Capacity Boilers (Above 50 Ton/Hour):

Designed for large industrial installations and power plants, these boilers deliver high outputs and incorporate advanced safety and efficiency features.

- Small Capacity Boilers (Below 10 Ton/Hour):

-

By End-Use Industry:

- Power Generation:

The demand from power plants remains a critical driver, as steam generation is central to electricity production in many thermal power plants. - Chemical Processing:

Industrial boilers play an essential role in chemical manufacturing processes, where precise steam generation and process control are necessary. - Food and Beverages:

In food processing and beverage production, boilers are used for cooking, sterilization, and other critical processes that demand reliability and efficiency. - Pharmaceuticals:

High-purity steam generation is crucial for pharmaceutical production, driving the adoption of advanced boiler systems in this industry. - Pulp & Paper, Textiles, and Others:

Additional industries such as pulp & paper, textiles, and various manufacturing sectors continue to rely on industrial boilers for their thermal energy needs.

- Power Generation:

For More Information About This Research Please Visit: https://www.maximizemarketresearch.com/market-report/global-industrial-boilers-market/24453/

Competitive Landscape

The competitive landscape of the industrial boilers market is highly dynamic, with numerous and regional players vying for market leadership. Companies are focusing on innovation, product quality, and comprehensive after-sales services to maintain a competitive edge. Some of the prominent players in the market include:

-

Cleaver-Brooks, Inc.:

Known for its high-performance boiler solutions, Cleaver-Brooks has a long-standing reputation for innovation and reliability in industrial applications. -

Hurst Boiler & Welding Company:

Hurst is recognized for its extensive portfolio of boiler systems, offering both standard and customized solutions to meet diverse industrial requirements. -

Miura America Co., Ltd.:

Specializing in compact and high-efficiency boilers, Miura America has carved out a niche in markets where space and energy efficiency are critical factors. -

Babcock & Wilcox Enterprises, Inc.:

With a presence and a focus on sustainable boiler technologies, Babcock & Wilcox continues to be a key player in driving market innovation. -

Bosch Industrials:

Bosch has diversified its industrial product range to include advanced boiler systems that emphasize energy efficiency, safety, and operational reliability.

Country-Level Analysis

United States:

The United States represents a significant market for industrial boilers, fueled by a robust manufacturing sector and a continuous drive towards technological advancement and energy efficiency. American industries are rapidly modernizing their boiler systems to meet stringent environmental regulations and reduce operational costs. Furthermore, government initiatives aimed at promoting energy efficiency and reducing carbon emissions are spurring the adoption of high-efficiency boilers. The U.S. market is characterized by a mature infrastructure that is increasingly investing in retrofitting and replacement projects to improve energy performance and operational safety.

Germany:

Germany is a leading player in the European industrial boilers market, driven by its strong industrial base and commitment to sustainability. German industries, known for their precision engineering and advanced manufacturing practices, are at the forefront of adopting cutting-edge boiler technologies. With a focus on reducing environmental impact, German companies are investing in boilers that offer high energy efficiency and lower emissions. The country’s regulatory framework, which prioritizes environmental protection and energy conservation, further supports the growth of the industrial boilers market. Additionally, Germany’s proactive approach to industrial modernization ensures that both new installations and retrofitting projects contribute to sustained market growth.

Browse More Reports by MMR:

Alloy Wheel Market https://www.maximizemarketresearch.com/market-report/alloy-wheel-market/215499/

Medical Automation Market https://www.maximizemarketresearch.com/market-report/global-medical-automation-market/20744/

About Maximize Market Research:

Maximize Market Research is one of the fastest-growing market research and business consulting firms serving clients globally. Our revenue impact and focused growth-driven research initiatives make us a proud partner of majority of the Fortune 500 companies. We have a diversified portfolio and serve a variety of industries such as IT & telecom, chemical, food & beverage, aerospace & defense, healthcare and others.

Contact Maximize Market Research:

MAXIMIZE MARKET RESEARCH PVT. LTD.

⮝ 3rd Floor, Navale IT park Phase 2,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

✆ +91 9607365656

🖂 sales@maximizemarketresearch.com

🌐 www.maximizemarketresearch.com